Development of a Lean Six Sigma Model and Resilient Supply Chain Using Modern Fuzzy Inference Approaches and Design of Experiments (Case Study: Asia Factory)

Keywords:

Six Sigma, Lean, Resilient Supply Chain, Fuzzy Inference, Design of ExperimentsAbstract

Objective: The present research aims to develop a Lean Six Sigma model and a resilient supply chain.

Methodology: To develop the Lean Six Sigma model and resilient supply chain using a grounded theory method, interviews with experts were conducted to examine the factors influencing the model's development. Then, the Delphi process and surveys from relevant experts (faculty members, managers of food companies, and supply chain experts) were used to finalize the list of dimensions and components via the grounded theory method and to determine the importance coefficient of each. Finally, the identified input variables were converted into explicit or numerical values using fuzzy inference algorithms by a defuzzification unit. Using the design of experiments technique, the 3^(k-p) method was applied to express the impact of each influencing factor on the output characteristics as a model. Considering the qualitative nature of the research method, the data obtained from the study were analyzed using NVIVO version 11 software in the first step. In the next step, MATLAB software was used for the fuzzy inference section, and finally, MINITAB software was used in the design of experiments section.

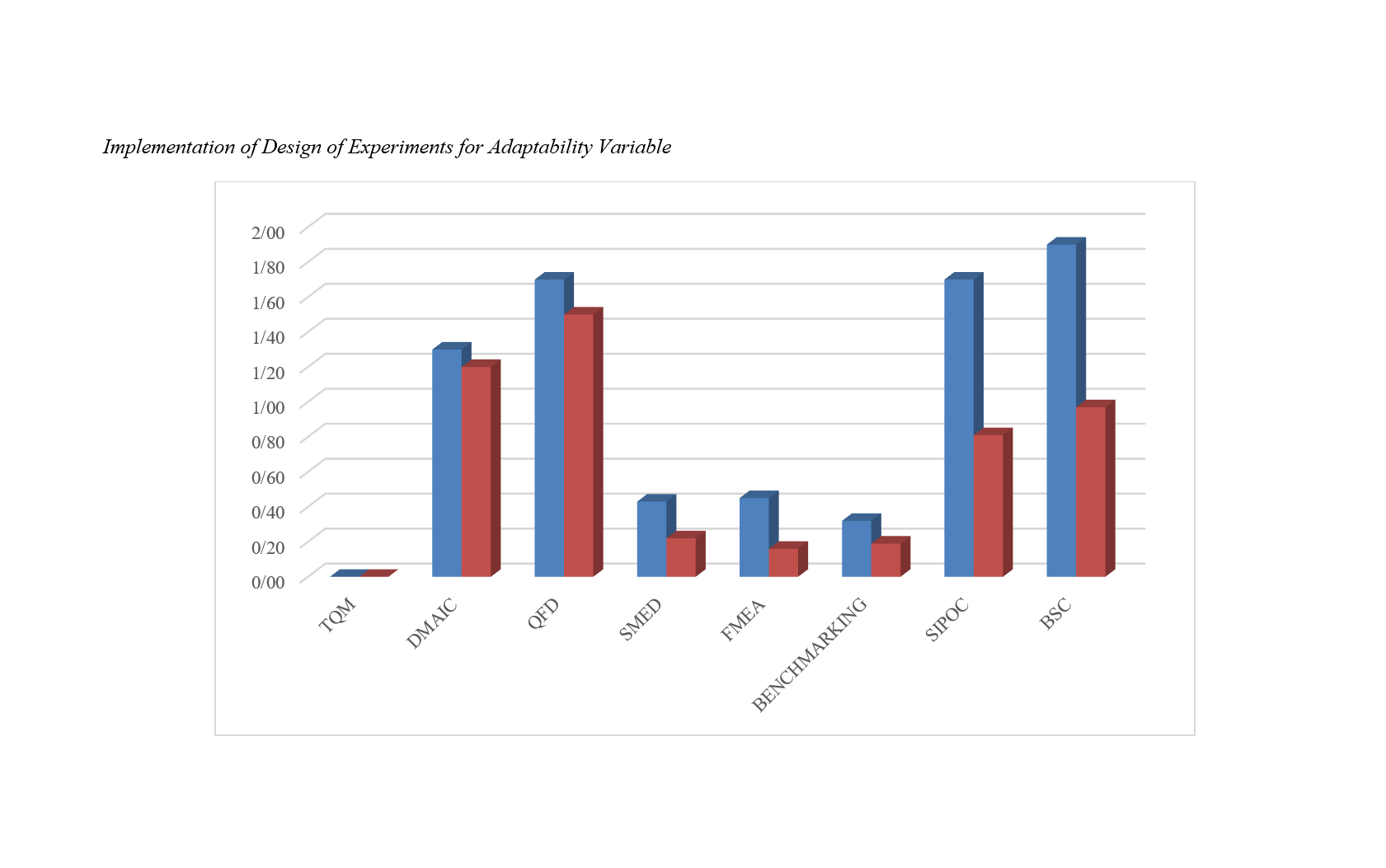

Findings: The results showed that all input variables affecting flexibility, capacity, and adaptability were significant at a 95% confidence level. Additionally, Total Quality Management (TQM) had the most significant impact on the variables of flexibility and capacity, while Quality Function Deployment (QFD) had the most significant impact on adaptability.

Conclusion: The proposed model, aiming for integrated information across the food chain, spans from primary agricultural production to the consumer, replacing human mechanisms and potential errors.

Downloads

Downloads

Additional Files

Published

Submitted

Revised

Accepted

Issue

Section

License

Copyright (c) 2024 Maryam Anjom Shoa (Author); Mojdeh Rabbani (Corresponding Author); Hassan Dehghan Dehnavi , Mohammad Taghi Honary (Author)

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.